Aluminium packaging recycling rates continue to increase, shows Q2 PRN data

According to data released by the Environment Agency in August, 42,243 tonnes of aluminium packaging were collected for recycling in Q2 2021 – an increase of almost 5% compared to the same period in 2020 (40,903 tonnes).

So far in 2021, 84,090 tonnes have been collected in total (an increase of more than 7,000 tonnes compared to Jan-Jun 2020), including more than 59,000 tonnes from kerbside, bring and on-the-go systems (up 11%), as well as c.23,000 tonnes recovered from incinerator bottom ash (up 7%).

With a target of 66% and a carry-in of 8,326 tonnes, the sector is on track to once again surpass its collection goal and achieve a record-breaking recycling rate. Indeed, according to the Environment Agency data, 67% of the annual target has already been achieved.

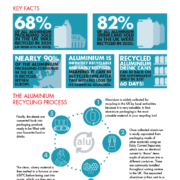

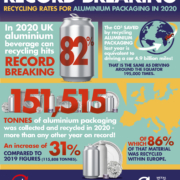

Tom Giddings, general manager of Alupro, commented: “In 2020, the UK reached its highest ever rate for aluminium packaging recycling (68%*), including an impressive 82%** for aluminium beverage cans. With numerous national lockdowns, remote working and reduced commuting, home consumption increased significantly. This saw kerbside collection rates soar.

“It’s pleasing to see that, despite higher targets and a return to the workplace, the UK has maintained record-breaking rates. Indeed, we’re over two-thirds of the way to achieving our 2021 target at only half way through the year!

“Such impressive figures can be attributed to greater public awareness about the benefits of aluminium recycling and positive action towards improving resource efficiency. While it’s difficult to predict trends for the rest of the year, we are optimistic that collection tonnages will continue to prove positive. As such, it’s important that we celebrate these successes, while maintaining focus on our goal of achieving close to 100% aluminium recycling across the UK.”

For more information about Alupro, or its MetalMatters and Every Can Counts behavioural change programmes, visit www.alupro.org.uk. To access the latest aluminium packaging recycling data, visit the National Packaging Waste Database (NPWD).

ENDS

*National Packaging Waste Data (NPWD) reports 2020 sales based on 2019 actual volumes. Rather than using 2019 production/sales volumes (as reported on NPWD) to determine the aluminium packaging recycling rate, the figure referenced in the text above (68%) uses predictive data for 2020 to provide a more accurate calculation. If 2019 production/sales volumes were used, the aluminium packaging recycling rate for 2020 would be 71%.

**The drinks can recycling rate is calculated based on sales data reported confidentially by drinks can manufacturers.