Brits back best practice DRS scheme design, finds YouGov research

- New research disproves claims that a variable rate DRS would be too complex

- 85% of respondents considered a variable rate system ‘easy to understand’

- 61% of respondents support higher deposits for larger containers

New research released earlier today (17 March) disproves the claim that a variable rate deposit return scheme (DRS) would be too complex for consumers. The YouGov insight suggests that 85% of Brits consider a variable system easy to understand and support higher deposits for larger containers.

Commissioned by Alupro, the aluminium packaging recycling organisation, 2,000 adults across Britain were surveyed about best practice DRS design and whether a variable rate deposit fee would add unnecessary confusion.

The results firmly rebutted this view, with more than four in five respondents suggesting that the concept of a DRS was easy to grasp (84%), and that the idea of varying the deposit value based on container size was equally simplistic (85%). Just over half of adults (55%) agreed that the deposit fee should be lower for smaller items and higher for larger ones, while three in ten (30%) thought the deposit amount should be the same across all sizes of packaging. Only a small minority admitted that they were undecided (15%).

These findings contradict government research from 2019, which suggested that a variable rate would be far too complex for householders.* Public understanding of deposit return schemes has changed significantly and appreciation of best practice design has fast become a discussion point.

Rick Hindley, executive director at Alupro, commented: “Adopting best practice design from the outset will prove pivotal to the long-term success of England, Wales and Northern Ireland’s deposit return scheme.

“Our independent research aimed to analyse real-world views regarding awareness of DRS design and understanding of deposit fees. According to the results, it’s safe to say that now, more than ever, householders want the best solution for the future – not the cheapest or the fastest.

“As the government discusses the design of our national scheme, we implore senior decision makers to take these findings into close consideration and not to choose simplicity over sustainability. The success of the scheme is important for every household, so we’re calling for their views to be recognised.”

Timiko Cranwell, Legal and Corporate Affairs Director at Budweiser Brewing Group UK&I, added: “Budweiser Brewing Group is committed to promoting circular packaging and responsible consumption. We believe that a variable rate deposit level is the foundation of a well-designed DRS, as it allows individuals to manage their own consumption, without incentivising the purchase of larger containers, or higher alcohol content, in the interest of saving money.”

Aiming to tackle plastic pollution, increase recycling rates, improve recyclate quality and minimise litter, England, Wales and Northern Ireland’s long-awaited DRS is expected to come into force in 2023. The scheme will see a deposit value added to the price of a beverage product in store, which will be refunded to the customer when empty packaging is returned to a designated collection point.

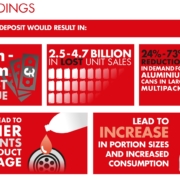

While a variable rate fee would see containers allocated with a deposit value based on container size, a flat rate model would apply a fixed fee to all beverage containers. This unsophisticated approach could see customers charged an additional £4.80 for a 24-can multipack (on top of product purchase price) compared to just 80p for a 2 litre plastic bottle.

ENDS

All figures, unless otherwise stated, are from YouGov Plc. Total sample size was 2001 adults. Fieldwork was undertaken between 18th – 19th February 2021. The survey was carried out online. The figures have been weighted and are representative of all GB adults (aged 18+).