Further Information

- As different aluminium-producing countries have different fuels which dominate their industries, some countries & regions have much higher carbon emissions than others per tonne of aluminium produced.

Chinese primary aluminium, which relies heavily on burning coal to produce electricity, will typically have a carbon footprint of 20 tonnes of CO2e per tonne of aluminium produced.

Chinese primary aluminium, which relies heavily on burning coal to produce electricity, will typically have a carbon footprint of 20 tonnes of CO2e per tonne of aluminium produced. European primary aluminium, which is largely powered by renewables such as hydroelectric power, will typically have a carbon footprint of less than 7 tonnes of CO2e per tonne of aluminium produced.

European primary aluminium, which is largely powered by renewables such as hydroelectric power, will typically have a carbon footprint of less than 7 tonnes of CO2e per tonne of aluminium produced.

- There are many factors which determine the ultimate carbon footprint of a product, so comparing different products at a high level is often not an accurate way to assess environmental impact. Conducting a complete Life Cycle Analysis (LCA), like this one, is the best way.

- Factors that can influence the carbon footprint of a product include:-

DISTANCE – How far a product travels, including it’s raw materials, throughout it’s entire life cycle.

DISTANCE – How far a product travels, including it’s raw materials, throughout it’s entire life cycle. WEIGHT – When it comes to packaging, less is more. Aluminium is very light and provides a completely effective barrier at thicknesses of only a few microns. This means that less aluminium is needed per pack, so the carbon emissions from each pack are also lower than for other heavier materials.

WEIGHT – When it comes to packaging, less is more. Aluminium is very light and provides a completely effective barrier at thicknesses of only a few microns. This means that less aluminium is needed per pack, so the carbon emissions from each pack are also lower than for other heavier materials. END-OF-LIFE – How a product is of its useful life is very important for its carbon footprint. Recycling and reuse retain both the materials and energy used to make the product, which in turn offsets the need to incur the high energy and carbon costs of primary aluminium production. Aluminium is infinitely recyclable, and the process is very efficient which means that keeping aluminium packaging in closed loops is the best way to reduce its carbon footprint.

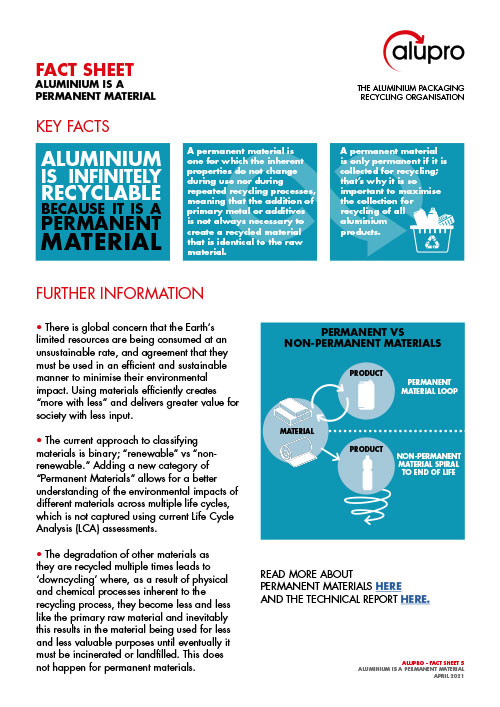

END-OF-LIFE – How a product is of its useful life is very important for its carbon footprint. Recycling and reuse retain both the materials and energy used to make the product, which in turn offsets the need to incur the high energy and carbon costs of primary aluminium production. Aluminium is infinitely recyclable, and the process is very efficient which means that keeping aluminium packaging in closed loops is the best way to reduce its carbon footprint.